Partnered with parent company The Specialty Manufacturing Co., SafeWay strives to continuously innovate our manufacturing capabilities, while tailoring our services to the varied needs of our customers. We are proud of the custom and ISO standard solutions we provide for industry leaders in agriculture, electronics, manufacturing and much more. As ISO standard and custom coupling manufacturers, we are willing to work with our customers to explore and execute unique solutions that leverage the use of plastic and metal materials, and varied finishing methods, such as hardening, annealing and various coatings.

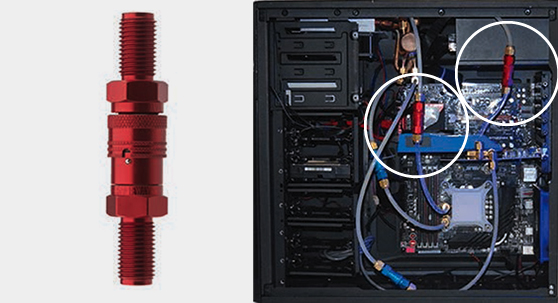

Reliable, Quick and Easy Modular Design When a new customer came to us in need of a fluid transfer coupling solution for cooling within electronics enclosures, we met the challenge head on. In this unique case, off-the-shelf couplers were too large and heavy for the confined space of their products. SafeWay engineers recommended reducing the

Simplifies Lubrication, and Maintenance Time is money when managing routine maintenance and lubrication of drive tracks on excavating equipment. A leading excavation machinery manufacturer designed a single zerk hydraulic system to deliver and bleed grease used to set/adjust track tension on their equipment. The system required a reliable and durable mechanism to inject lubricant, and

Eliminates Errors and Streamlines Changeover When a leading manufacturer of high-performance lubricants needed to be certain workers could quickly and easily distinguish among their fluid lines’ many standard quick disconnects, the production workers sometimes made costly connection errors that cross contaminated fluids. The lubricant manufacturer turned to SafeWay for a solution to their error-prone fluid-transfer

SafeWay: Leading Quick Disconnect Coupling Manufacturer

SafeWay hydraulic quick disconnect couplings have a solid reputation for ease of use, zero leakage and minimal restriction of flow during system operation. Since our founding in 1969, all SafeWay fluid transfer products have been designed, fabricated and assembled in USA. We are proud to have pioneered the first two-way sleeve quick-connect coupler, and have continued pursuing similar design and value-added engineering solutions ever since.

Today’s impressive product line includes a broad selection of industrial and agriculture hydraulic quick disconnect couplers. These include various ISO interchanges, heavy-duty connect-under-pressure designs, and innovative flush-face, non-face, non-spill models. Our product specifications and quality are second to none. We frequently work with OEM’s to design special products for their unique applications.

Today SafeWay’s hydraulic connector product line is impressive and includes quick connect/disconnect hydraulic connectors used in a broad range of industries. Its hydraulic connectors meet specifications common in industries such as agriculture, construction, hydraulic jack, and other mobile equipment applications. SafeWay products are used in every industry where a fast and dependable fluid connection is required.

SafeWay quick couplings and quick connect hydraulic fittings are standard equipment on a wide variety of products, including farm tractors, snow plows, sprayers, pressure washers, front-end loaders, skid-steer loaders, wire pullers, earth moving equipment, hydraulic rams and jacks, turf equipment, mining operations, chemical plants, steel mills, hydraulic hand tools, test benches, tractor trailers, combines wing plows, rescue equipment, and offshore drilling rigs.

Additionally, SafeWay hydraulic quick connect fittings have a solid reputation for ease of use without leakage, and with minimum restriction of flow during system operation. Many hydraulic quick couplers look alike on the outside and interconnect because of exterior dimension requirements within a given interchange. But performance specifications, ease of use, and overall reliability vary greatly from brand to brand. SafeWay quick couplings have advantages over other manufactured products in their reliable design features, the high-quality materials used in production, and rigorous product testing. Product specifications and quality are second to none!

With a host of achievements to look back on, The Specialty Mfg. Co. is adding one more to the list by celebrating 120 years of service this September of 2020. A top manufacturer of custom and customized miniature valves, process control components, fixturing and pool components, Specialty Mfg. Co. (SMC) proudly serves a wide variety of industries across their home in the Midwest and beyond.

Collaboration with industry leaders to set new standards for liquid cooling components means big opportunities for SafeWay. The OCP (Open Compute Project) is a nonprofit organization that shares designs and best practices for data center products and solutions. Among the group are leading computer hardware and software companies.