Non-standard QDs often lead to better system design and, surprisingly, lower overall costs.

Contributed by Joe Engel and Nick Goenner, Specialty Manufacturing Co.

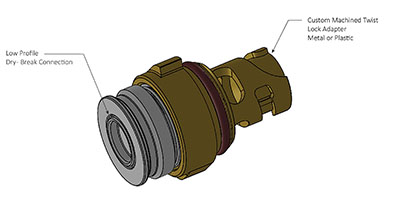

This oil-change adapter features a custom twist-to-lock connection.

Most quick-disconnect coupling manufacturers focus on offering standard products in dozens, if not hundreds of different sizes and types. Many times, off-the-shelf QDs work fine for a given task. They meet the necessary performance requirements and tend to offer ready availability and a reasonable price.

But often a standard product is not the best choice, especially when a fluid-power engineer must make compromises to the overall machine design to accommodate a stock QD. In such cases, a custom design can often improve equipment efficiency, reduce space requirements and lower the total system costs.

Quick couplings are fittings used to mate fluid lines with equipment that requires repeated connections and disconnections. Their design is straightforward: a male end is inserted into a female socket to make a secure, leak-tight seal — and the assembly can be quickly undone with minimal effort. The products are designed for easy hand operation in countless hydraulic and pneumatic applications, such as in mobile and industrial machines, hydraulic and pneumatic tools, food and packaging equipment, analytical instruments, and medical and dental devices.

Consider custom

Unfortunately, most QD manufacturers see custom designs as either an afterthought or a nuisance; or the producers lack customization capabilities altogether. A handful of fluid-power companies tend to take a different approach.

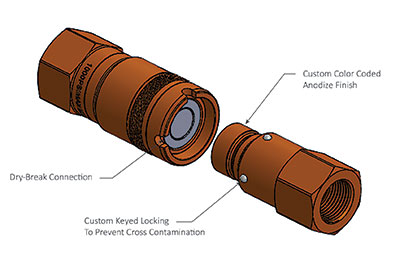

This dry-break coupling for lubricant handling is color coded for easy identification, and custom key locking prevents cross contamination.

For example, SafeWay, a division of Specialty Manufacturing Co. based in St. Paul, Minn., offers a catalog of standard agricultural and industrial quick couplings along with a mix of ISO and non-standard versions. In addition, SafeWay takes a collaborative approach to solving quick-disconnect application challenges. The company designs and manufactures couplers to fit the specific need, so the design engineer is not forced to choose an off-the-shelf part that may be over- or under-built. This also allows them to be more flexible on the design of the rest of the hydraulic system.

Our experience in both our standard product line and solving issues with our customer’s custom applications provides us with a deep pool of knowledge that can be applied to avoid the unforeseen challenges and pitfalls that those less experienced in the industry may fall into.

By sharing ideas and concepts with our customer, a design often emerges that suits the customer’s performance requirements while also fitting our manufacturing capabilities to minimize the cost as much as practical.

Quick-coupling options

Quick-couplings are much more complex than they seem on the surface, so it is important to work with a supplier that understands every aspect of the product. Adapting them to particular applications tends to require a different approach, because virtually every aspect of a quick-coupling can be altered and refined to better serve a customer’s application. Such criteria can include:

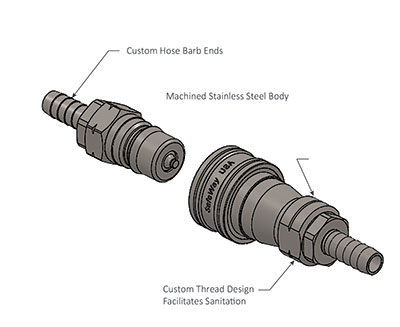

A quick disconnect for beverage dispensing applications has a sanitation-friendly design made of stainless steel.

The connect/disconnect action: Different connection styles are available to suit a variety of applications. One-handed, push-pull connections make coupling as quick and easy as possible. Threaded connections eliminate excessive wear caused by side-loaded or high-impulse applications. Sometimes the locking mechanism is removed entirely because another mechanical device is used to couple the QDs and maintain them in that state, as in multi-coupling or “rack-and-panel” applications.

Size: Size is closely related to the amount of flow that the coupler will accommodate. Larger sizes will allow more fluid to pass with less pressure loss through the coupling. Internal features also matter — sometimes a smaller coupling is feasible if the flow passages are designed to minimize pressure loss.

Flow and pressure capability: Important considerations related to size, these parameters can definitely be tailored to the design. Generally larger couplers will flow more freely, but typically struggle to contain as much pressure as their smaller counterparts.

Vacuum capability: Vacuum adds additional considerations to the design, but capable engineers can easily accommodate this capacity into a QD.

Shape: Shape and geometry are somewhat dependent on the coupling’s features. For example, a “dry-break” style coupling will have a different appearance than a traditional “agricultural” style coupling due to its nature. However, outside of these features, shape can be adjusted to fit the needs of the application, usually for mounting or user-friendliness reasons.

Materials: Materials offer flexibility to tailor the design. If the strength of steel is not essential, brass may be a better option to suit corrosion or chemical compatibility requirements. Or aluminum may be desired for its light weight and ease of applying color via anodizing.

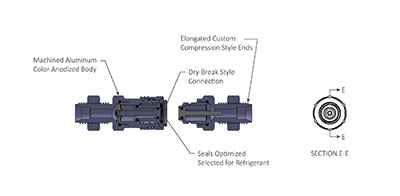

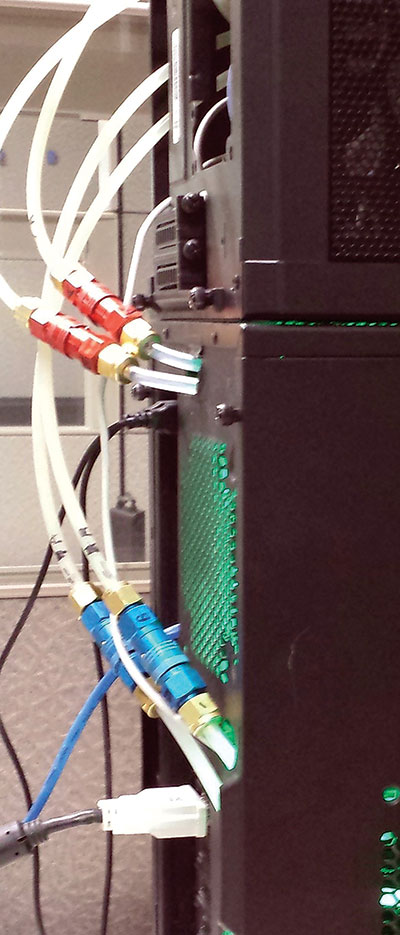

Engineers at Specialty Manufacturing designed special compact, leak-free couplers to handle refrigerant in QuantaCool’s electronics cooling system.

Coatings and finishes: Various coatings are available to increase corrosion protection, reduce friction, harden surfaces to resist wear, or apply color coding as the application demands.

Type of threads: An experienced manufacturer can offer much more than just standard pipe or O-ring boss threads, such as metric and British options. Designing the preferred connection right onto the coupler eliminates the need to add an adapter to an off-the-shelf coupler, saving weight, cost, and eliminating potential leak paths.

Valving: The type of valve will affect the performance and functional characteristics of a coupling. The valve type can be tailored to achieve extreme durability, flow performance, or minimize spillage upon disconnect, to name a few considerations. Sometimes customers request no valving at all to maximize flow through the coupling.

Seals: It is very common to select seals appropriate to the application, typically to suit the media and temperatures. Offerings include Buna, Viton, EPDM and more exotic compounds such as Aflas and perfluoroelastomers. Seals can also be crimped or bonded into place to suit demanding applications.

Environmental extremes: Engineers can design the QD to handle temperature extremes or operate under rugged environmental conditions. This is closely related to the seals and materials discussed previously.

Additional considerations: Other customizable design parameters include color, sleeve lock (prevents accidental disconnects) and interchangeability, or lack thereof, with other designs.

Cost-effective manufacturing

Customers should expect that any QD manufacturer has a clear understanding of the many performance attributes needed for a given application, and should be willing and prepared to discuss the unique characteristics and the QD options, materials and cost elements to optimize the long-range performance of the device in their application.

Users should also look for a high quality manufacturing partner that has a history of successful innovation. Specialty Mfg., for example, is ISO 9001:2015 certified, which demonstrates a strong focus on tight controls in manufacturing and assembly processes. One of the most unique aspects of the company is that production facilities include seven distinct manufacturing disciplines and engineering specialists. These include: metal machining, wire EDM, plastic injection molding, stamping, grinding, assembly and quality control.

Unlike manufacturers that heavily rely on subcontractors, these disciplines are vertically integrated at Specialty Mfg. Vertical integration permits tight control of an entire process, project management and costs. In rare instances some secondary operations are outsourced. These are mapped into the production cycle of a given project to streamline coordination, so the customer only needs to deal with a single point of contact—rather than facing the headaches of juggling multiple vendors and purchasing agents.

Customers should also expect a reasonable turnaround time from order to delivery. Six months is the typical window for a project from initial engineering consultation with a vendor to the delivery of a pilot run. Projects can be sped up in situations where the base design is proven for functionality and the natural iterative process is minimal.

Finally, there’s the overall economics of a custom design. Manufacturers who are strong adherents of designing for manufacturability generally offer products with lower costs and better consistency and reliability. While costs for customized solutions are very volume-dependent, a focused and efficient producer can be very competitive outside the commodity market.

By truly understanding the customer application, the design-for-manufacturability process often eliminates unneeded features of an off-the-shelf coupler, ensures intelligent choices in the materials used, reduces the overall footprint of the system being designed, and ensures dimensional optimization—while applying the most appropriate manufacturing disciplines to optimize efficiency and overall cost.

Safeway

safewayhyd.com

QuantaCool required an economical, dripless QD that is color coded for easy assembly and with a sleeve-lock to prevent accidental disconnect.

Today’s data centers, gaming and many other electronic systems operate with increased processing speed and graphic quality — with the added challenge of increased thermal management. More and more manufacturers are looking for alternatives to traditional air cooling to disperse the heat generated by their high-power electronics systems. A reliable, safe and passive two-phase cooling system can provide a low-cost, efficient and effective alternative to air or water cooling.

QuantaCool, Chadds Ford, Pa., helps solve the cooling challenges of the electronics industry with its Microchannel Heat Pipe (MHP) technology. The system passively circulates refrigerant instead of pumped water, and cools more efficiently while minimizing the risk to both electronics and personnel. Compact high-flux heat absorbers (cold plates) rely on phase-change principles (boiling and evaporation) to remove and dissipate large quantities of heat from high-intensity sources. The heat is passively rejected to the outside surroundings.

Secure and leak-free couplers are critical components in this two-phase cooling design. QuantaCool needed a unique refrigerant coupler to meet the demands of their new electronics cooling system. Off-the-shelf component options were too large and expensive, and many manufacturers were not interested in producing the short-run couplers that the application required. QuantaCool approached the engineering team at SafeWay to design a unique coupler that fits the size and material requirements, at a cost-effective price. The new coupler not only met the demands required for thermal management in the reduced footprint of QuantaCool’s PolarBox and PolarRak systems, it also simplified the assembly process.

Application requirements

For the new cooling system, QuantaCool required a quick-disconnect coupler with unique requirements for size, material and pressure—beginning with smaller production runs. These included:

While other manufacturers were not interested in developing a new product with initial low volume production runs, SafeWay’s flexible, collaborative approach to product development made it possible to green light the project.

Based on the application requirements, SafeWay’s design engineers developed initial product drawings, and a collaborative team of SafeWay and QuantaCool experts enhanced the product design. SafeWay then produced 3D prototypes, initiated a small pilot run and qualified performance. Additional on-site testing led to enhancements in the lubricants and seals, creating a final ready-for-production coupler solution.

Installation advantages

The new dripless couplers let QuantaCool easily precharge the products with refrigerant before shipping to customers. And at customer installations, the color-coded, quick-disconnect couplers make it simpler and easier to install QuantaCool’s products on-site.

SafeWay added a locking collar for a more-secure connection, to prevent accidental disconnects during assembly or operation. Customized ends allow the couplers to connect to tubing or be panel mounted. And the specialized design ensured the couplers operate in an environment where the media does not lubricate the coupler components. Finally, with a critical eye on the bottom line, SafeWay provided QuantaCool with the small production runs they needed, at a cost-effective price.

QuantaCool now has an electronics cooling system that is leak free, modular, flexible, and efficient. Their custom coupler solution from SafeWay helps them assemble products more efficiently, while helping their customers install QuantaCool’s products more easily.

QuantaCool

quantacool.com

Source: Fluid Power World